SASIL Srl

Trattamenti minerari integrati alle tematiche ambientali europee

COSA FACCIAMO

La SASIL S.r.l. opera nel Biellese Orientale nel settore minerario dal 1975, con miniere nei Comuni di Curino e Masserano e stabilimento in Comune di Brusnengo.

SASIL produce sabbie feldspatiche, sabbie silicee, sabbie di vetro lavate e feldspati per l’industria del vetro, della ceramica e dei sanitari.

SASIL gestisce un ciclo di trattamento minerario completo: lavaggio, attrizione, macinazione, classificazione, flottazione, essiccazione, separazione magnetica, lisciviazione, recupero e filtrazione delle frazioni più fini.

Negli ultimi anni si è specializzata nel recupero degli scarti industriali di diversa provenienza ma su base vetro, mettendo a punto innovativi processi di trattamento.

Collateralmente ha sviluppato alcuni progetti di valenza ambientale ed energetica che hanno già permesso di ridurre notevolmente le emissioni di CO2 come conseguenza delle riduzioni dei consumi energetici.

Inoltre, ultimamente ha messo a punto un sistema di trattamento del quarzo per ottenere una silice purissima utilizzata nel vetro dei pannelli fotovoltaici di ultima generazione con un guadagno energetico del 20% rispetto ai tradizionali.

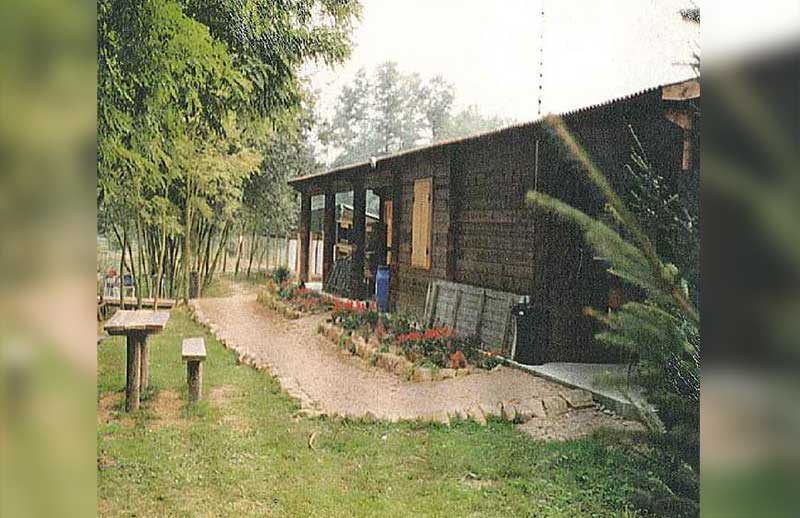

Le miniere esaurite vengono recuperate a parco attrezzato per essere fruibili gratuitamente.

La SASIL collabora anche sistematicamente con istituti universitari per progetti di ricerca e sviluppo.